18" x 65",200L Upflow Duplex Water Softener, Clack WS1TTCI Digital Metered Controller, 1" , 6.8 m³/hr

Couldn't load pickup availability

Share

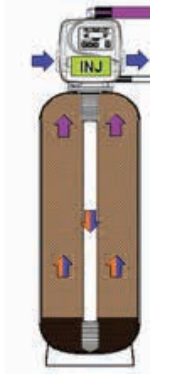

The process of a standard downflow softener is that hard water flows down through the resin bed and when regenerating the brine does the same. As a result of this, the top of the bed is regenerated first and some of the hardness travels through the resin and can reattach. However, in a counter current softener, the brine passes down the riser tube and up through the resin bed which results in the resin at the bottom of the vessel getting regenerated first.The resin at the bottom is in effect super regenerated which means there is less chance of hardness breakthrough which in critical applications is important. For the resin at the top there isa clear escape for the hardness so that doesn’t reattach.

In essence a counter current regenerating softener is around 5 to 10 percent more efficient on salt usage and uses less water to regenerate making it a sound ecological and financial choice for those looking to increase their green credentials.

Benefits

- Salt economy (5-10% saving)

- Same capacity using less salt

- Water savings

- Environmentally friendly

- Lower brine discharge

Specification

- Inlet/Outlet: 1"

- Drain: 3/4"

- Max Flow: 6.8 m³/hr

- Pressure: 1.5 to 8 bar

- Valve: WS1

| Valve | Volume | Salt | Size | Flow Rate | Capacity |

|---|---|---|---|---|---|

| WS1CI | 50L | 130g/l | 1054 | 2m³/hr | 8.3m³ |

| WS1CI | 100L | 130g/l | 1465 | 4m³/hr | 16.7m³ |